REPAIR & MAINTENANCE

Of Storage Tank

STORAGE TANK REPAIR & MAINTENANCE

REPAIR & MAINTENANCE

The tanks play a vital role of storing oil and gas products as they await transportation or further processing. These products are highly inflammable. They have to be well inspected, maintained and repaired to prevent cases of catastrophic failure. This paper explores these procedures, in relation to the American Petroleum Institute (API) 653 guidelines.

WHAT DO WE DO?

We have

extensive experience in construction, repair and maintenance of different sizes of Storage Tanks. Our scopes vary from designing, procurement, supply & erection of different capacity and product stored. INNOVATION LAND ENGINEERING / EPC L.L.C. has delivered innovative solutions for storing products at ambient temperatures.

We offer a comprehensive package of services for tank projects that includes concept definition, design and detail engineering, fabrication, procurement, site development, foundation and tank construction, painting and coating, commissioning and startup, and operator training. Our projects have included everything from single tanks to complex storage terminals.

We execute our projects on a lump-sum, turnkey basis, performing every phase of the work ourselves whenever possible. Our integrated business model translates into shorter project schedules, lower costs, improved quality control and reduced risk for the customer. Because we provide single-point responsibility, our customers don't have to worry about the duplication of effort, delays and design incompatibilities that can arise when multiple contractors are involved.

Our solutions include atmospheric storage systems for a variety of industries. We can provide standard storage configurations or custom-design systems for specific needs. Our expertise includes:

- Fixed-roof

- Self-supporting/supported cone roofs.

- Self-supporting dome roofs.

- Stiffened umbrella roofs.

- Floating-roof Internal and external operations - Welded steel pan, pontoon, or double deck designs.

As an optional service, we offer our Total Tank Management program, which includes everything from tank inspections and cleaning, to environmental assessment reviews, repairs and modifications. This program allows our customers to concentrate on their core business while INNOVATION LAND ENGINEERING / EPC L.L.C. manages all tank related activities, providing cost-effective maintenance and regulatory compliance.

Tank Repair & Maintenance Projects Definition

Repairs and Changes

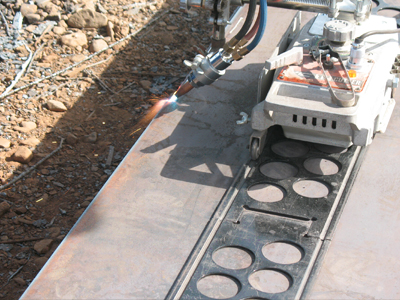

If anything was noticed during the inspection and cleaning of the tank, this means repairs are going to be planned. There are several ways to repair oil storage tanks. The API standard for repairs starts with exterior repairs to the shell plating of any storage tank. This can also lead to upgrading to the height of the shell if the owner feels that more storage capacity is necessary.

The process then moves on to repairs of the defective welds and shell penetrations. The roof and bottom are then fixed according to standards, with the final fixes being done to the seals. The traditional way of doing this is via welding, which can mean the need to shut down operations fully while the repair is being done to avoid any fire hazards. Nowadays, cold-curing using chemical compounds is also an option.

Replacement

For severe cases, a tank might need to be replaced. This usually happens if the damage is too severe or the tank is failing to meet any of the standards for fuel storage. Full replacements can be costly, though, so it’s best to aim for proper maintenance so that you don’t end up having to replace your oil storage tanks too often. Proper maintenance can ensure that your storage tanks will be able to last a long time. Additionally, regular repairs will help patch up damage so that the tank will still be useful.

Overall, knowledge of maintenance procedures and repair options can extend the service life of your oil storage tanks by many years. Look for a reputable provider of maintenance services if you think you can’t handle the job yourself. Hiring the pros is still your best option when it comes to this type of business.

KEEP IN TOUCH, CONTACT US NOW

Be Close To Us.

Ariha Engineering EPC

Basra - Iraq